ZutaCore and Chatsworth Products (CPI) take the Stage at BISCI 2024

At last week’s Building Industry Consulting Service International (BICSI) Winter Conference and Exhibition, ZutaCore’s own Tony Medler joined Sam Rodriguez from CPI for a joint presentation titled “How Liquid Cooling is Changing the Landscape of Data Centers.” BICSI is a conference geared to the global information and communications technology (ICT) community, and it has become an international hub for forward-thinking, solution-generating, progressive ICT topics.

If you were not lucky enough to head down to Sunny Florida for this conference, don’t worry because we’ve got you covered! Below is a recap of what they presented. Sam and Tony are experts in their field, with Tony being a Sales Executive at ZutaCore and Sam being the Senior Product Manager of cabinets, Containment, and industrial Solutions at Chatsworth Products.

The Need for Liquid Cooling – A Perfect "Heat" Storm

As explained in their presentation, data centers are challenged due to increased processor heat density and power dissipation. These data centers will transition from 100% air-cooled to a hybrid of air and liquid cooling – with the transition from single-phase to two-phase liquid cooling happening much sooner than air to single-phase.

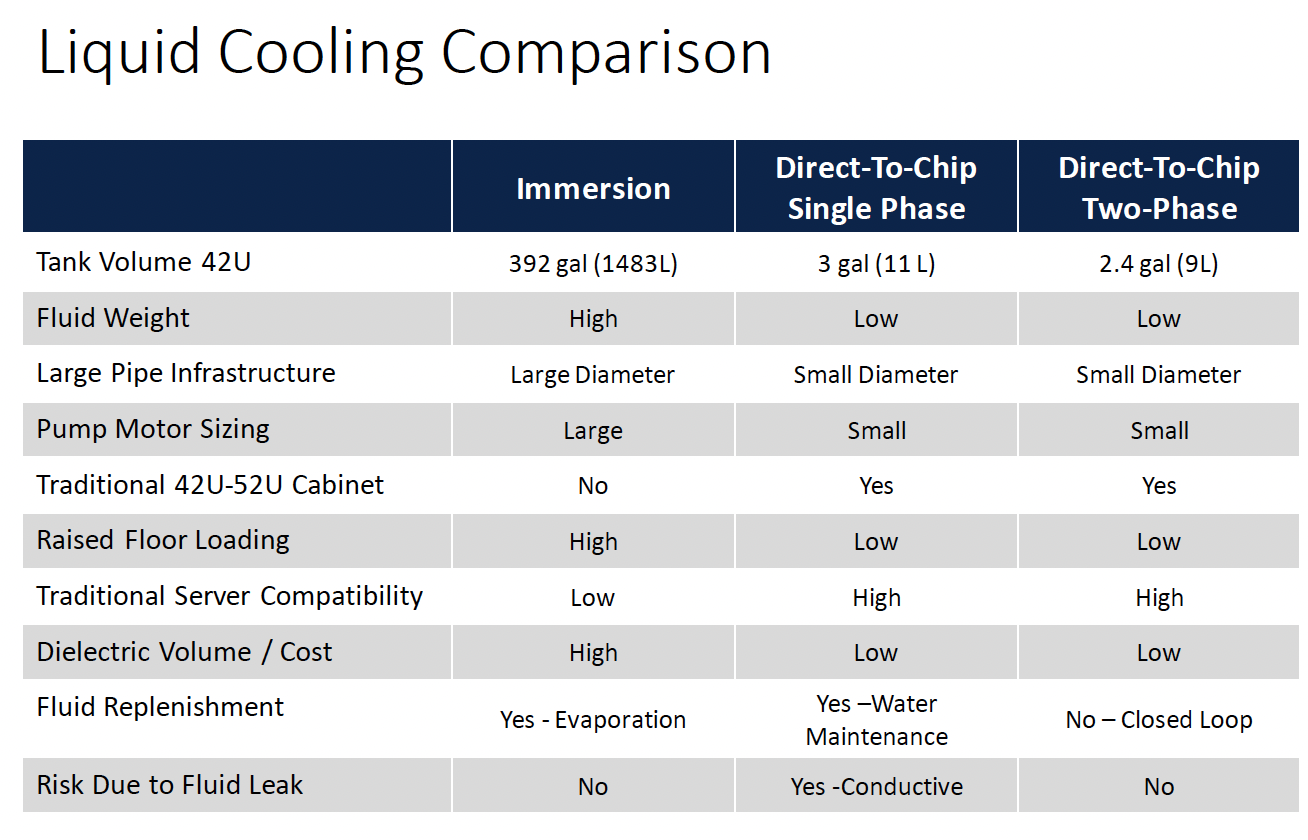

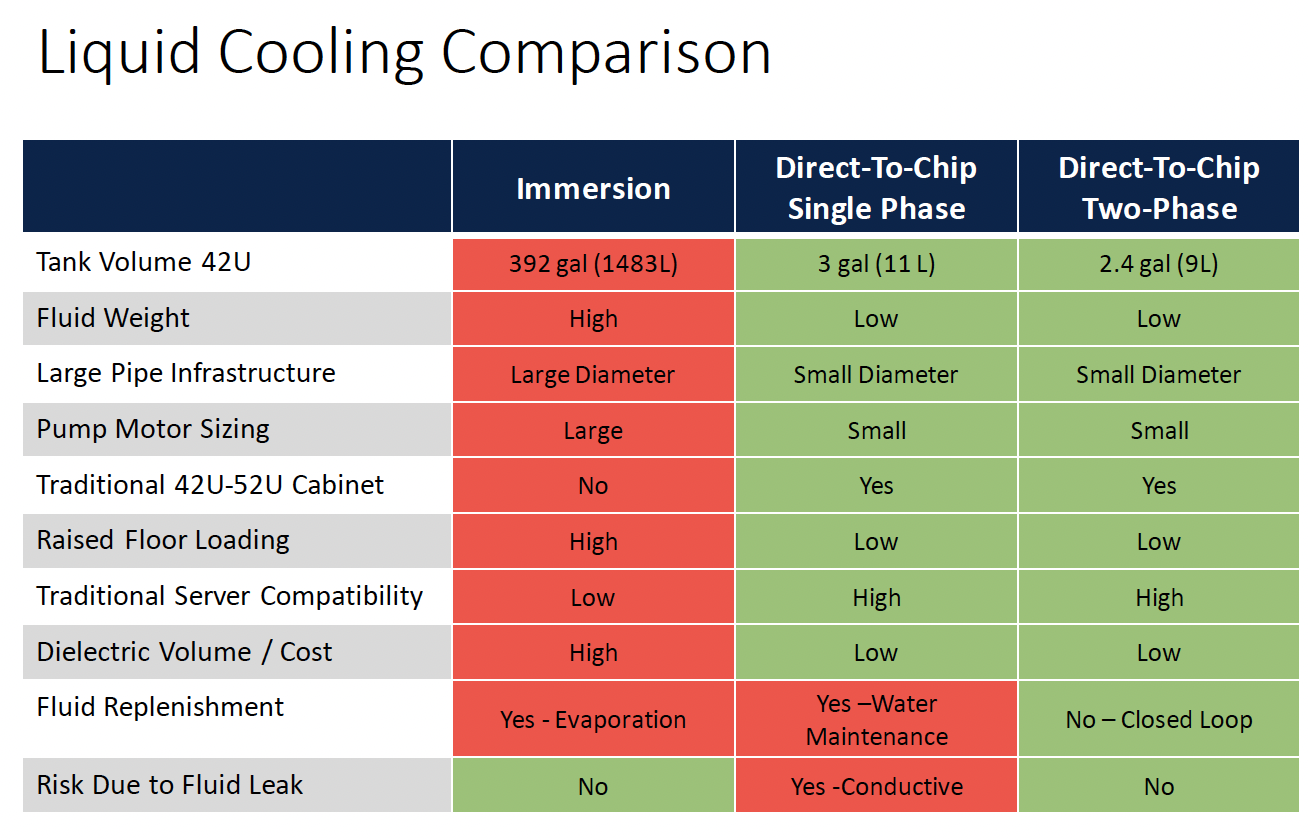

Today, there are two types of liquid cooling technologies. Full immersion cooling is directly immersed in a non-conductive liquid and includes single-phase and two-phase Immersion Cooling. In contrast, direct-to-chip cold plate cooling is a method with a heat transfer fluid circulated to the high heat source and includes single-phase and two-phase direct-to-chip.

The advantages of each cooling solution can be summarized in the following two Liquid Cooling Comparison Chart. As you can see, direct-to-chip, two-phase cold plate cooling requires little to no data center infrastructure/ server change, supports high Thermal Design Power (TDP) processors, and features a heat transfer fluid pumped through the server (not conductive) with a two-phase pool boiling for even heat distribution. Furthermore, the low-pressure system of this solution reduces the risk of leakage, and the closed-loop design preserves the heat transder fluid level, integrity, and viscosity of the liquid indefinitely.

How Data Centers Benefit from Two-Phase Direct-to-Chip Cold Plate Cooling Solutions

Because two-phase direct-to-chip cold plate cooling solutions reuse heat locally or externally, this solution is critical for driving net-zero emissions. Below are some of the cold plate technology’s other benefits for data centers:

- Cools up to and beyond 1500W processors and 100kW/Rack

- Safely upgrades existing data centers by increasing node density by 2X and CPU performance by 30% (eliminates throttling).

- Closed loop and waterless liquid cooling

- Reduces OPEX (0.5 million USD/year saving on 1 MW data center.). This can reduce power consumption by up to 35% and reduce maintenance downtime and costs

- Supported by leading server manufacturers such as Dell, ASUS, Pegatron, and SuperMicro

Case Study: A Top Three USA Bank

Sam and Tony walked the audience through a recent case study. This involved a bank looking for a solution to be more efficient in reaching their net zero goals by 2030. However, the problem this bank faced was that it had limitations on their power and space. To solve this, the customer worked with ZutaCore to retrofit its HyperCool® solution on existing Dell servers to deliver greater density and reduce power consumption by 25% without expensive server upgrades. The result is that HyperCool is now liquid cooling Intel Xeon processors (20kW of CPU cooling) inside a Chatsworth Products (CPI) ZetaFrame® Cabinet System, saving the bank 6kW of power per rack.

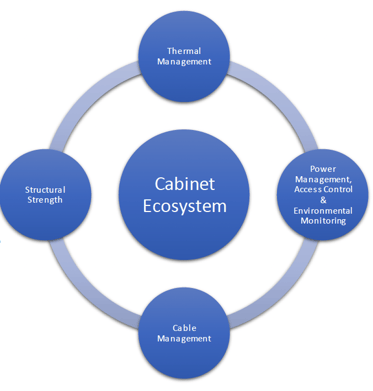

The Importance of a Cabinet Ecosystem

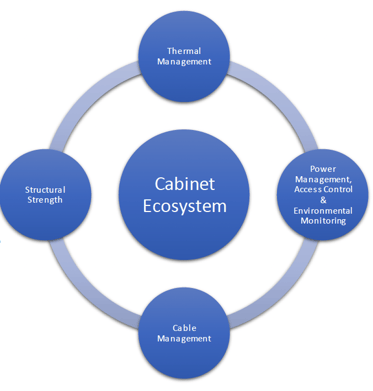

As the case study highlights above, a cabinet ecosystem is crucial. This is ideal for white space management and deploying a future-proof architecture for evolving high-density ICT technology. This comprehensive, scalable solution can also seamlessly and efficiently address changes in IT equipment, power densities, heat loads, and cabling.

Direct-to-Chip Liquid Cooling Can Co-Exist with Current Data Center Designs

Sam and Tony also explained how direct-to-chip liquid cooling can co-exist with current data center designs with the proper cabinet specification. Direct-to-chip components are optimized in size and placement and allow compliance with rack and cabinet sizing standards (TIA-569-C section 6.3.9 Racks and Cabinets.). It also provides sufficient space for cable management options to meet structured cabling standards for separation of telecommunications from power (TIA-569-C section 9.3.1; TIA-942 Section 7.3)

Below is an example of HyperCool in a ZetaFrame Cabinet Ecosystem. The cabinet is optimized for integration with direct-to-chip liquid cooling, features intelligent power management and monitoring with intelligent PDUs, and has physical security and access control.

The Future is Direct-to-Chip Liquid Cooling

Tony and Sam wrapped up their presentation by recapping how direct-to-chip liquid cooling enables organizations to overcome their cooling needs for powerful processors and denser systems. They can do this while also increasing their sustainability with on-demand, self-regulated cooling that improves the data center's energy efficiency. As an added benefit, heat reuse can be used for various other things, such as heating homes, pre-heating schools, office buildings, and hot water supply.

To learn more about ZutaCore integrated with CPI's ZetaFrame Cabinet System download the industry report.

Alison Deane

Alison Deane