1 min read

Unlocking the Future of AI Cooling: Two-Phase, Direct-to-Chip Liquid Cooling

As AI superchips push the boundaries of power and performance, the heat they generate is becoming a critical challenge for data centers. With...

3 min read

Arnon Cohen

:

Aug 27, 2024 12:26:31 PM

Arnon Cohen

:

Aug 27, 2024 12:26:31 PM

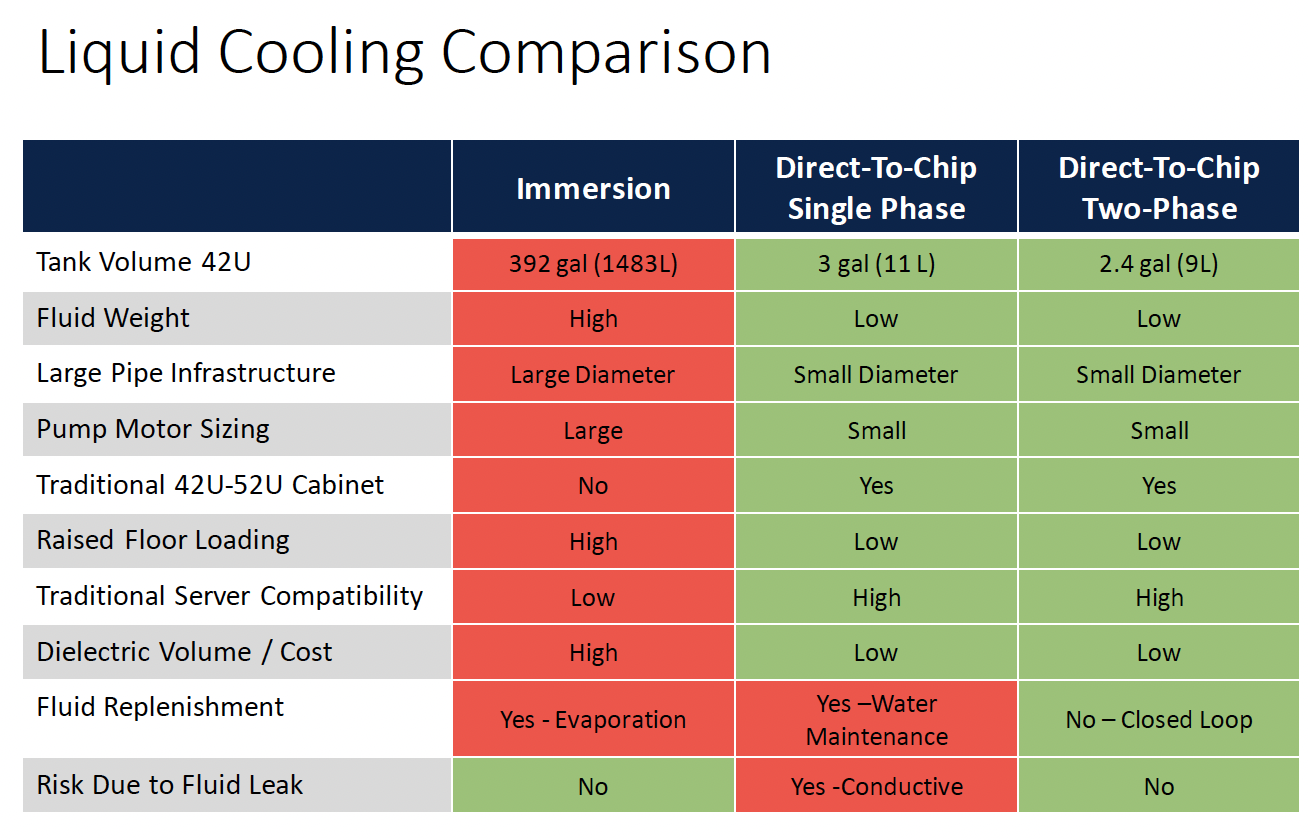

With the massive build-out of AI factories and HPC data centers, liquid cooling has suddenly become one of the most critical requirements of the decade as hyperscalers scramble to control their heat and footprint while still contributing to global sustainability goals. There is no question that this technology is being adopted at an unprecedented rate, but there are still a lot of questions in the market over what the differences are between two-phase direct-to-chip liquid cooling and immersion liquid cooling and they are not the same!

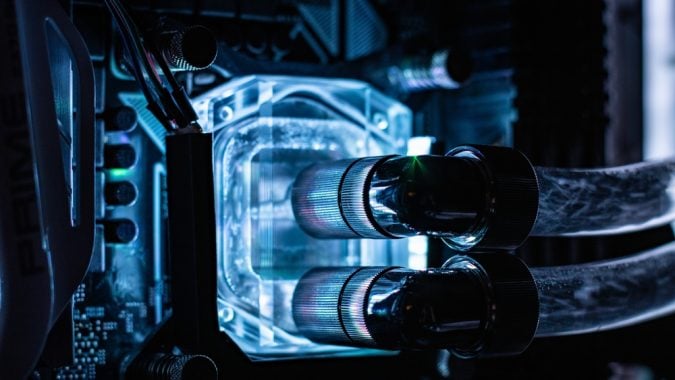

Both types of cooling use a waterless liquid at a high level. However, with Immersion liquid cooling, all the servers and other components are completely submerged in a heat transfer fluid in big, heavy tanks. In contrast, the two-phase direct-to-chip process brings only a small amount of heat transfer fluid to a cold plate that is placed directly on top of the high heat flux source, such as CPUs and GPUs.

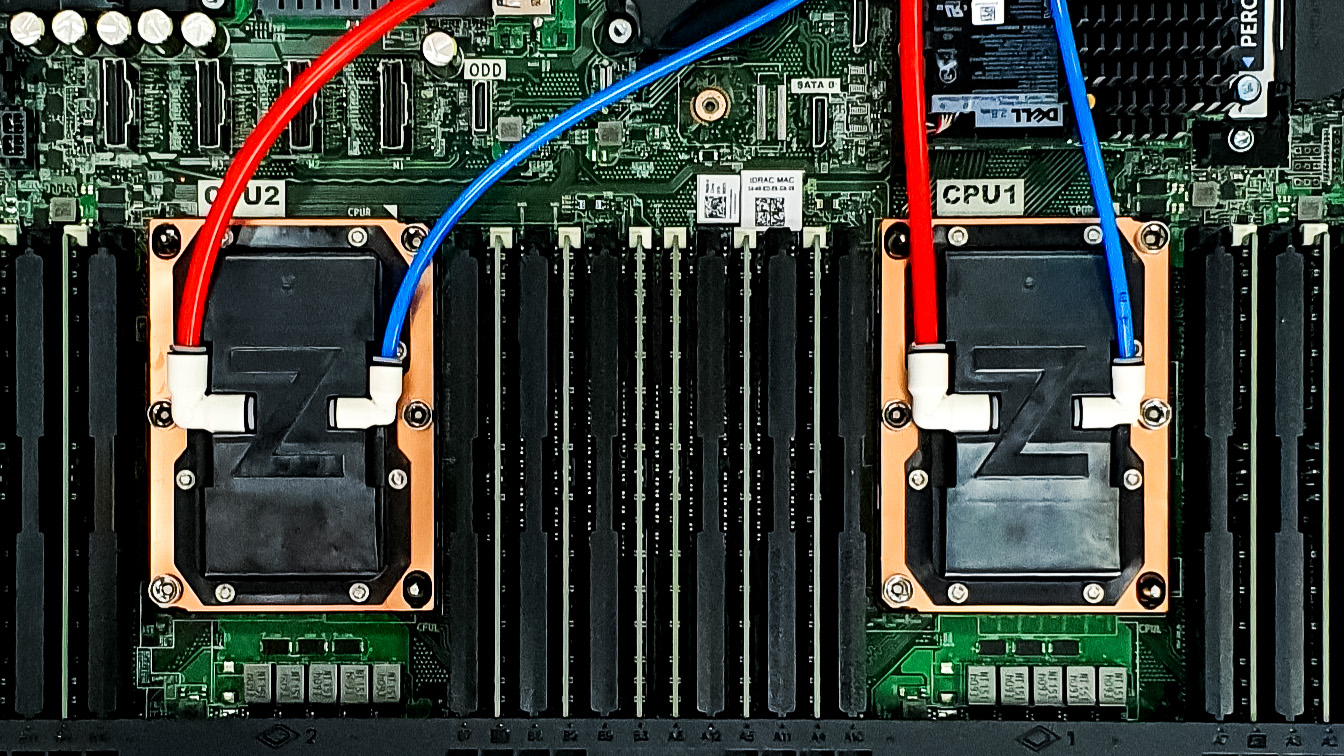

As an example, the below picture shows ZutaCore cold plates sitting on NVIDIA H100 GPUs. As you can see, the heat transfer fluid never touches the equipment, since it flows in a closed loop system. If this were showing immersion cooling, the entire rack would be completely submerged in the liquid. To put in perspective how much fluid each solution uses….a 100kW rack using two phase direct-to-chip technology uses less than 4 gallons of heat transfer fluid, vs. immersion cooling that needs over 100 gallons per rack.

In contrast to two-phase direct-to-chip cooling, immersion cooling requires significant data center infrastructure investment because large and heavy tanks filled with liquid are now needed to hold the equipment. There are several disadvantages of this liquid immersion cooling approach:

The Two-Phase, Direct to Chip Liquid Cooling Advantage

In contrast to immersion cooling, the two-phase direct-to-chip cooling approach such as ZutaCore® HyperCool® uses a highly efficient, two-phase boiling and condensation process moving large amounts of heat off the processors and away from servers. This two-phase liquid cooling technology is scalable and can be deployed in new or retrofitted data centers, with an ability to cool 2,800 watts and beyond. Other two-phase liquid cooling advantages include:

With dozens of HyperCool deployments in production, ZutaCore has emerged as the clear leader of two-phase, direct-to-chip liquid cooling technology. To learn more, download the eBook.

Immersion cooling submerges the entire server in liquid, while direct-to-chip cooling uses cold plates on top of CPUs or GPUs to transfer heat without liquid ever touching the components. Direct-to-chip systems require less fluid and are easier to maintain without infrastructure overhauls.

Two-phase direct-to-chip cooling like ZutaCore HyperCool handles thermal design power (TDP) over 2,500 watts, while immersion cooling typically struggles above 700 watts. It’s more scalable, energy-efficient, and doesn’t require major hardware changes or special server modifications.

No. A two-phase, direct-to-chip liquid cooling system like HyperCool® uses a closed-loop design, so the fluid never vents into the atmosphere during operation or maintenance. The liquid has very low global warming potential (GWP) of 1.0, and is non-corrosive and non-conductive. In 2023, ZutaCore committed to bringing a non-PFAS fluid to market inconjunction with our partners, by 2026.

1 min read

As AI superchips push the boundaries of power and performance, the heat they generate is becoming a critical challenge for data centers. With...

1 min read

The data center industry is evolving rapidly, and liquid cooling is at the forefront of this transformation. With processors becoming more powerful...

2 min read

Having optimal server capabilities are essential for organizations engaged in compute- and data-intensive applications such as high performance...