2 min read

ZutaCore Wins “Best Supercomputing Cooling Innovation” at ISC 2025

It’s a wrap for the ISC High Performance 2025 Conference and Exhibition in Hamburg, Germany…..and ZutaCore® came home with the Gold! It’s HyperCool®...

2 min read

Alison Deane

:

Apr 23, 2024 12:31:39 PM

Alison Deane

:

Apr 23, 2024 12:31:39 PM

As we prepare to attend the 2024 OCP Regional Summit in Lisbon, Portugal, one of the most prevalent trends we keep seeing in the industry is the migration towards modular data centers. In fact, according to Omdia Research, the revenue for modular facilities built onsite using prefabricated components rose from about $2.3 billion in 2020 to $3.25 billion in 2023, and by 2026, this market will be worth $5.25 billion. This is a significant opportunity and as you will see at the OCP show, waterless cold plate cooling is highly compatible for modular data center applications. ZutaCore’s very own Shahar Belkin and Lilach Butchmits not only published a white paper on this topic on the Open Compute Project’s (OCP) website at this link, but Shahar will also be discussing this in a presentation in Lisbon on Thursday, April 25th at 8:45 am.

Shahar’s talk and the whitepaper explore the dynamic world of liquid cooling, focusing on direct-to-chip cooling and its advantages and environmental implications. Waterless cold plate cooling enables very efficient and cost-effective operation in modular data centers, enabling rack densification while keeping them cool, and reducing power consumption and costs. Furthermore, when facility water is used to cool the heat transfer fluid, the water outlet is at a constant temperature of 70°C, enabling an efficient and cost-effective heat reuse option.

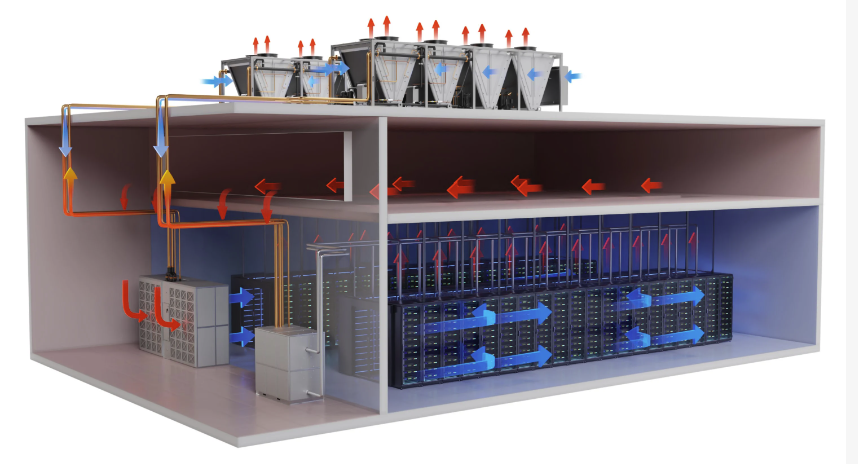

Two Configurations – An All-In-One Approach

The white paper presents two sample configurations of “all-in-one” prefabricated data center in a container using ZutaCore’s HyperCool® technology. These use cases combine facility structure, IT equipment, power infrastructure, and cooling into one shippable enclosed unit, providing a plug & play computing solution.

Option 1: 1MW liquid cooled data-center configuration - using ZutaCore direct-to-chip waterless cooling system, with a facility water distribution, will allow a modular container to contain a 1MW data center using the latest and strongest CPUs with a PUE of 1.12, and even 1.07 when used under climate conditions such as in Denmark. Each container will contain 16 racks, each rack will support 63 kilowatts(kW) of IT.

Option 2: 350kW liquid cooled data-center configuration – using ZutaCore direct on chip waterless cooling system, with free air flow, will allow a modular container to contain a 350kW data center with a PUE lower than 1.07. Each container will contain 16 racks, each rack will support 20 kilowatts (kW).

The Conclusion: The first configuration, providing 1MW, enables a very efficient operation by densifying the racks while keeping them cooled and with heat reuse option, suitable for example, for the HPCs intense computing needs. Furthermore, this configuration provides a facility water outlet at a constant temperature of 65℃, hence enabling an efficient and cost-effective heat reuse option. Using this solution will require only one modular data center as opposed to, for example, using 90kW modular data centers, that will require using 11 modular data centers. The proposed solution will need only 10% of the space needed for the alternative.

The second configuration providing 350kW, is a cost-effective solution with completely waterless operation, suitable, for example, for Telco providers. Both configurations can be related as building blocks that can be either incorporated as part of a data center or as a standalone solution.

The HyperCool Advantage in the Modular Data Center

In the modular data center, direct-to-chip cooling takes liquid cooling to the next level. It involves integrating two phase cold-plate directly onto the surface of semiconductor chips. This approach minimizes the thermal resistance between the chip and the heat transfer fluid, ensuring rapid and efficient heat removal. As a result, chips can operate at optimal temperatures, pushing the boundaries of computing power without compromising reliability.

When moving to waterless cold plate cooling, the energy efficiency is embedded in the cooling system efficiency and IT power efficiency. The processors are not cooled by air anymore, which enables the internal air temperature coming to the servers to be higher.

Come See Us at the Show at Stand B7.

To learn more about our waterless, direct-to-chip liquid cooling solution download our eBook.

2 min read

It’s a wrap for the ISC High Performance 2025 Conference and Exhibition in Hamburg, Germany…..and ZutaCore® came home with the Gold! It’s HyperCool®...

2 min read

“GenAI is the new engine that will fire investments to edge data centres.”— Rajiv Ranjan, IDC India As India experiences explosive demand for AI...

1 min read

What do you get when you combine the best two-phase, direct-to-chip liquid cooling with world-leading energy-efficient air treatment and climate...